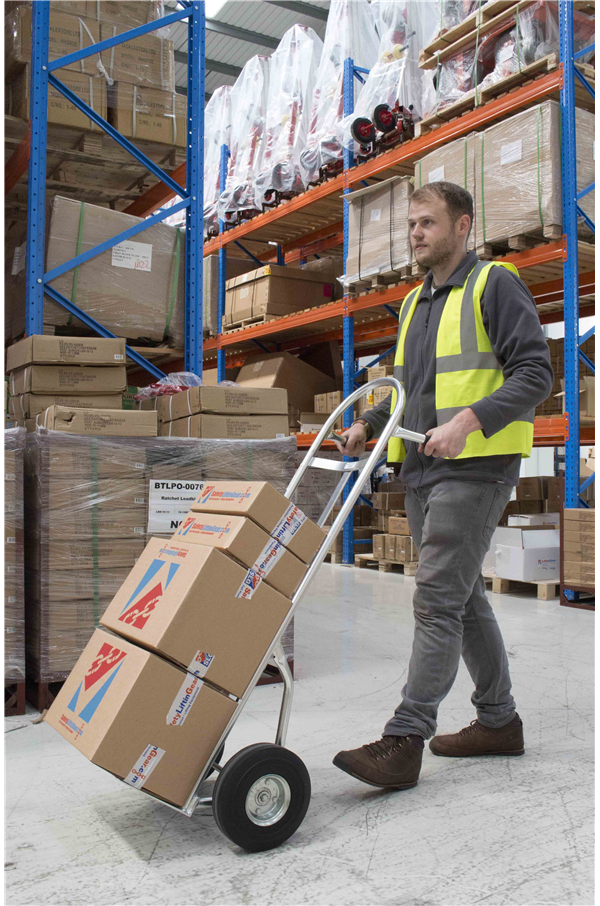

Any employee that works in any field that has to do with the transportation or storage of products or items will be in potential danger of pulling a muscle or fracturing a bone if he is careless for even a moment. This obvious danger to the employees’ well-being is the main reason why most companies forego making their workers carry any load by hand but instead use hand trolleys to drastically decrease the chance of injury, but unfortunately not get rid of it entirely.

There are many different types of hand trolleys, from the small equipment carriers with the built-in drawers, to the heavy-duty steel ones designed to move everything from a box of products to a baby elephant. They range from two-wheelers to four, and their exact shape and size tell you all you need to know about which are for small objects and short distances and which are meant for more difficult to move items. The smaller ones still pose certain risks depending on the exact items that they carry, but the real threat to the operator’s safety are the larger ones that carry heavy loads that can seriously hurt anyone that’s not careful. To make sure that you stay safe while using either, you will need to always keep in mind the characteristics of the trolley as well as the workplace.

When it comes to the hand trolleys themselves, the most important thing is choosing the right one for the task at hand. If the company you work for only transports one item, then there is a good chance there will only be one kind that can be used every time, however, if there are more than one, it is advised that you take some time to familiarize yourself with how each of them works and moves. The most care should be dedicated to the loading and unloading process as that is the time when most accidents seem to occur. Always keep in mind the position of your fingers when setting down the items and the posture of your back when lifting them (naturally you should always lift with the legs). And lastly, never rush since it could lead to you sustaining an otherwise easily avoidable injury or cause the product to slip or get damaged.

There are a few things to watch out for when it comes to the condition of the workplace itself as well. Always make sure that you have as clear of a line of sight as possible in order to watch for any obstructions or dangers in front of you. These include any cracks, wet spots and any uneven place. Speaking of uneven, watch for inclines or declines as they can either cause you to lose control or have to exert more force that you are capable of. In addition, always make sure that you accurately judge the width of the isle you are going down as you might put yourself in a sticky situation that you won’t be able to get out of.

The most important word while operating a hand trolley is patience. Never rush and never put more weight than you can manage just so you can finish sooner, as both of these will end badly.