In today’s age of computers and robotics, manual human labour and with that human error are becoming a thing of the past. I’m not saying that humans are completely redundant, but their role in the manufacturing process has shifted towards the part which involves creativity and the supervision and maintenance of the machines that do all the work.

In order for your company to stay competitive on the market, you have to keep up with the new technology. CNC or Computer Numerical Control machines are the way of the future. Depending on your company’s needs, you can either invest in a CNC machine or you can outsource the production of your components and avoid all the costs that come with operating and maintaining a CNC machine.

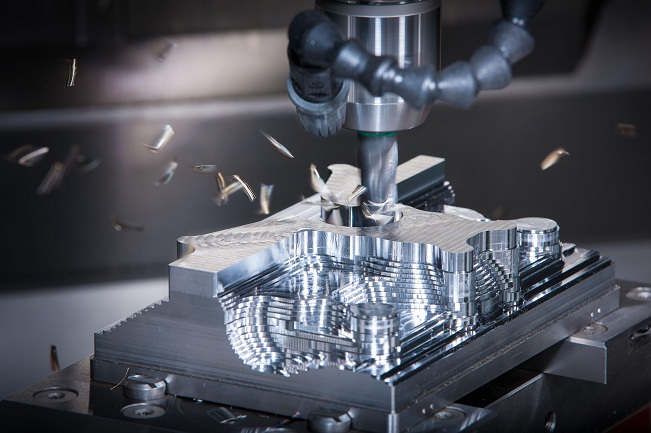

Machining steel components with CNC technology has a number of advantages including precision, control, consistency, and the fact that you can produce complex components that are practically impossible to make manually.

With manual machining, the worker himself manipulates all the tools and the material by hand in order to produce the desired component. This, of course takes great skill, but also a lot of time and intense focus. A machinist can only work on one piece at a time and a momentary lapse in concentration may result in an error. With CNC machining steel, on the other hand, the involvement of the operator is reduced to a minimum. The machine can be left mostly unattended once the program starts running. One operator can supervise multiple CNC machines at the same time.

Probably one of the greatest benefits of machining steel with CNC technology is the level of precision and consistency. The CNC machine will follow the same steps of the program in exactly the same way, over and over again. In other words, you can create a large number of components that have the identical measurements. This level of precision is simply impossible to achieve for a human machinist no matter how highly skilled he or she is.

Another great benefit of CNC machining is flexibility. As the name itself implies, Computer Numerical Control machines are basically state-of-the art computers that operate a set of tools thanks to special programming. The program of a CNC machine is relatively easy to change from producing one component to another. You can make all kinds of modifications to a component by simply modifying the program, and you can store the program itself and use it again when needed. This enables fast switching between different products.