Every industrial facility that deals with liquids and chemicals needs to have an effective spill response system in order to prevent small accidents from becoming huge disasters. Having the right spill containment products and providing proper training for your employees is crucial to implementing an effective spill response system. The response plan will include assessing the risk, picking the right PPE equipment, confining the spill, stopping the source of the spill, implementing cleanup, decontaminating the spill site and completing the necessary reports are all steps of a proper spill response.

However, your company should also include your own procedures into these steps, as having things like designated areas where the spill containment products are stored and training a spill response team are things that should be unique to your facility. Let’s get into more detail about how the spill containment procedure should look like.

First and foremost, when a spill occurs, you need to assess the risks that can affect the environment, property and most importantly, human health. This can require some investigation, or it could be instant if the spilled liquids are something you or your employees were working with. The two important things to note when assessing risk is how large the spill is, and what are its dangers to the spill responders and the surrounding environment.

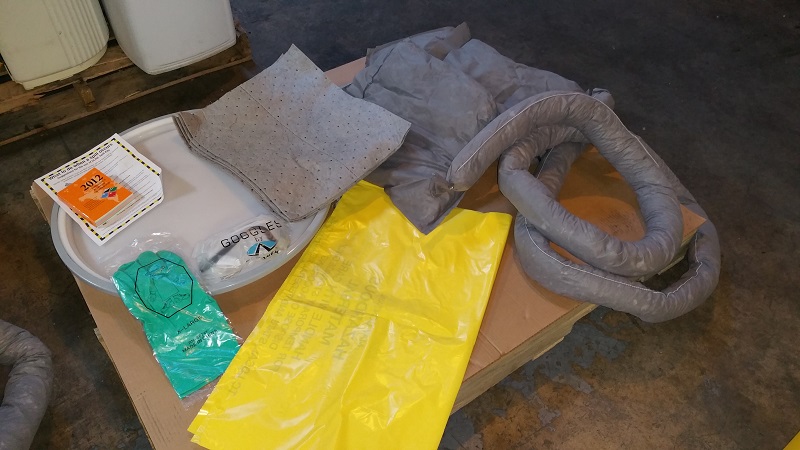

Next, you need to buy the right personal protective equipment and spill kit. If the danger and the substances of the liquid are unknown, you should assume the worst and use the highest level of protection. Then, you should use the appropriate spill kit and absorbents. You’ll usually find universal absorbents which absorb solvents, coolants, oils and water, oil-only absorbents that absorb oil but not water, and chemical absorbents which absorb most acids, caustics and other unknown liquids.

Once you’ve confined the spill, you need to stop the source, which can happen before or after the spill is confined, depending on the size and extent of the spill. This can be as simple as turning a drum or container upright or plugging a leak. Once the source of the spill is stopped, the liquid s should be transferred from the leaking container to a new one.

Lastly, it’s time to make another assessment of the incident, and develop a plan for a complete cleanup. The first thing to do is to make sure the responders have all the necessary equipment and supplies to deal with the incident. Once the spill is dealt with, the entire area needs to be decontaminated by neutralizing or removing the hazardous materials that may be present. This can include removing contaminated media and disposing of the personal protective equipment.